* Following the success of the 707, 727, 737, and 747 jetliners, the Boeing company began investigation of a new generation of aircraft, one result being a large twinjet, the "767", which led in turn to the scaled-up "777". Both these big jetliners proved successful, with the 767 featuring a number of military derivatives, and in the 21st century they are being followed by a new generation twinjet, the "787". This document provides a history and description of the 767, 777, and 787 jetliners.

* In the 1970s, jetliner manufacturers introduced "wide-body" airliners that could haul larger numbers of passengers, Boeing being very successful with their 747 jumbo jet. Boeing management began to think there was a market for a smaller wide-body, focused on the transcontinental market. The expected retirement in the 1980s of Boeing 707 and Douglas DC-8 jetliners enhanced that sense of opportunity; the jetliners established in the 1960s were not only aging, the tougher environmental regulations and the high fuel prices of the energy crisis due to the 1973:74 Arab oil embargo made cleaner and more efficient airliners attractive.

Boeing initiated a "7X7" program to develop the new wide-body. By 1976, the 7X7 had congealed into a twin-aisle aircraft with three jets and a tee tail, something like a scaled-up Boeing 727. Availability of sufficiently powerful turbofan engines reduced the number of engines to two; the tee tail lingered somewhat longer, but was ultimately replaced by a conventional swept tail arrangement with a low-mounted tailplane, that seen as having better stall characteristics. Passenger capacity was envisioned as 180 to 200 seats.

In early 1978, Boeing began to peddle the "767" to prospective customers, with United Airlines being the launch customer. Development then moved ahead towards production. Boeing was also working on the smaller 757 jetliner in parallel; turning out two major aircraft at the same time was a strain, reduced by sharing technology between the two aircraft, most notably the advanced cockpit. Interestingly, aircrew have to step up into the cockpit on the 767, while they step down into the cockpit on the 757.

Sub-assemblies were also farmed out to industrial partners -- Fuji, Kawasaki, and Mitsubishi of Japan; Alenia of Italy; Vought and Grumman in the USA; and Bombardier of Canada. Construction of the first "767-200" began in mid-1979, with the prototype performing its initial flight on 26 September 1981. There had been consideration of a "767-100" with lower passenger capacity, but it didn't happen. United Airlines took delivery of its first 767-200 in September 1982. The 767-200 was available with three different maximum take-off weight specifications.

One of the prototypes, incidentally, was modified for use as a US military testbed, the "Airborne Optical Adjunct (AOA)", later renamed the "Airborne Surveillance Testbed (AST)". It had twin ventral fins and a "hump" running down the top of the forward fuselage to the rear of the wing roots. It was used to test an infrared imaging missile-tracking system, and possibly some other kit. The AST was retired in 2002.

BACK_TO_TOP* As it emerged, the 767-200 was of what would become a conventional jetliner configuration, with a low-mounted wing, a high-bypass turbofan on a pylon under each wing, and a conventional tail arrangement. All flight surfaces were swept. Construction was primarily of aircraft aluminum, but with extensive carbon-epoxy composite structures as well. The wing had a sweep of 31.5 degrees at quarter-chord, and a dihedral of 6 degrees. As was typical of its Boeing jetliner predecessors, it had an elaborate set of flight control surfaces, the trailing edge of each wing featuring, from tip inward:

There were four spoilers in front of the outboard flap, and two in front of the inboard flap -- the spoilers being used for roll control, as airbrakes, and for "lift dumping" on landing to make sure the aircraft settled down on the runway. There was a full-span six-segment slat on the leading edge of the wing. The leading edge of the wing outboard of the engine was electrically de-iced; the inboard leading edge was not de-iced. The tail flight surfaces were of generally conventional arrangement, with rudder and elevators, although the tailplane also had variable incidence. The tail flight surfaces were not de-iced. All flight controls were hydraulically operated.

Two engine options were offered initially, including the General Electric (GE) CF6-80 and Pratt & Whitney (PW) JT9D-7 high-bypass turbofans -- with the more powerful Pratt & Whitney PW4000 added later. There was a range of subvariants of these engines that powered 767 jetliners, with different engine subvariants not only used on different 767 variants, but as options for each 767 variant. The bewildering menu of engine subvariants is best not pursued here in detail; enough to say that the range of thrust was from just under 214 kN (21,800 kgp / 48,000 lbf) to over 267 kN (27,200 kgp / 60,000 lbf), with bigger 767 variants, as might be expected, tending to use more powerful engines.

Of course, the engines had thrust reversers, standard kit for all modern Boeing jetliners. The engine inlets featured de-icing. There was an auxiliary power unit (APU) turbine in the tail section for engine starting and ground power.

___________________________________________________________________

BOEING 767-200:

___________________________________________________________________

wingspan:

47.57 meters (156 feet 1 inch)

wing area:

283.3 sq_meters (3,050 sq_feet)

length:

48.51 meters (159 feet 2 inches)

height:

15.85 meters (52 feet)

fuselage diameter:

5.03 meters (16 feet 6 inches)

empty weight:

79,925 kilograms (176,200 pounds)

max take-off weight:

136,075 kilograms (300,000 pounds)

max cruise speed:

900 KPH (560 MPH / 485 KT)

service ceiling:

13,135 meters (43,100 feet)

range, nominal:

5,185 kilometers (3,220 MI / 2,800 NMI)

___________________________________________________________________

There was a fuel tank in each wing and in the wing center section, providing a total fuel capacity of 63,216 liters (16,700 US gallons). The nose gear had twin wheels and retracted forward; the main gear had four wheels each, in a 2x2 bogie arrangement, and retracted from the inner wings towards the fuselage. The wheels had anti-skid brakes.

There were two flight crew, using a "glass cockpit" with six CRT displays that was advanced for the era. The avionics included radios, navigation aids, and a weather radar, with some variation in particular kit as per customer request. A typical two-class arrangement seated 216, both classes featuring two aisles, with six seats across for 18 first-class passengers and seven seats across for 198 tourist passengers. There were toilets and a galley fore and aft, with toilets in the center section as well. There were fore and aft passenger doors on the left side of the fuselage, with matching service doors on the right side of the fuselage, and an emergency exit over each wing. There was a baggage hold underneath the passenger compartment, with fore and aft baggage doors.

Although no new-production freighter version of the 767-200 was built, from the late 1990s, a number of 767-200 jetliners were converted to "767-200SF (Special Freighter)" configuration, featuring a large loading door on the left forward fuselage and cargo handling facilities.

* The 767-200 was followed by a series of improved variants:

A "767-400" had been considered, but it never flew, Boeing finally seeing no market for a short-range / high capacity version. There was talk of an even longer-range "767-400ERX', but it didn't happen. By the summer of 2025, Boeing had sold over 1,300 767s of all variants, and it continues in production, the focus being on the 767-300F freighter. Boeing has given some thought to an up-engined "767-XF", based on the 767-400ER, but there's been no commitment to it.

With rising fuel prices, winglets became an attractive upgrade option for older 767s without the raked wingtips, with winglet-fitted 767-300ER jetliners re-entering service in 2009 and many airlines obtaining the upgrade. The winglets were estimated to save a significant 6% in fuel burn.

BACK_TO_TOP* The 767 has had a number of military sales. The Italian Air Force ordered four as mid-air refueling tankers, with deliveries in 2007 and 2008. The Italian tankers were basically 767-200ER machines fitted with a boom refueling system and the stronger flaps of the 767-400, to permit take-offs at a lower rotation angle, as dictated by the boom under the tail. The boom system externally resembled that of the old Boeing KC-135 Stratotanker -- but it was a new design, with greater reliability, lower parts count, and lighter weight than the KC-135 boom unit. The boom unit also included a hose and drogue system, and there were wingtip pods for probe-and-drogue refueling. A total of 100 external lights, some of them infrared, were added to aid in tanker rendezvous operations.

The tankers also featured the more modern cockpit layout of the 767-400, enhanced with military avionics -- particularly military communications and "identification friend or foe (IFF)" -- and a cockpit workstation for the "remote aerial refueling operator (RARO)", as opposed to the tail workstation of the KC-135. The RARO workstation included a second seat for training purposes, with the crew members wearing helmet-mounted stereo displays. The pilot and copilot also had a new flat-panel display to allow them to keep an eye on refueling activity. The enhanced military communications suite added VHF & UHF radios, a satcom link, and a Link 16 digital datalink.

The tanker could carry up to 73,000 kilograms (161,000 pounds) of fuel; it could also haul a maximum of 35,000 kilograms (77,000 pounds) of cargo on 19 military-style pallets, or 200 passengers and 9,000 kilograms (20,000 pounds) of cargo. The first machine was integrated by Boeing, but the later machines were integrated by the Finnmeccanica / Alenia Aeronavli facility in Naples, which was already performing 767 freighter conversions. All four aircraft were delivered in 2011.

* In the early 1990s, the Japanese Air Self-Defense Force (JASDF) was interested in acquiring an airborne early warning (AEW) platform, the prime candidate being the Boeing E-3 Sentry, based on the 707 airliner, the standard AEW platform for the US Air Force (USAF) and NATO. However, by that time the 707 was out of production, and so Boeing proposed a 767-based platform fitted with E-3 electronics instead. The JASDF acquired four "E-767" AEW aircraft, with deliveries in 1998 and 1999. The E-767 is discussed elsewhere, along with the 707 / E-3.

The JASDF also ordered four "KC-767J" tankers, with deliveries from 2008 to 2010. That was quite a departure for the Japanese, who have long avoiding obtaining military systems that could imply an offensive posture. The KC-767J was derived from the 767-200ER, and like the Italian machines had a convertible configuration, allowing it to be used as a cargo or troop transport if necessary. The KC-767J only had the boom refueling unit; hose-and-drogue units weren't required. Deliveries were from 2008 through 2010. Italy had actually been the launch customer for the KC-767, but their deliveries had been delayed by problems with the hose-drogue pods, a difficulty that did not affect the JASDF's tankers.

* In 2003, the US Air Force announced a deal for a lease of 100 KC-767s from Boeing, with these machines capable of carrying communications or signals intelligence pallets to provide additional capabilities. The lease was to run ten years, and the USAF would then buy the aircraft. Unfortunately, that was at the time of a set of very public corporate meltdowns, most notably of the corrupt Enron firm; Congress was not happy about the deal, with Arizona Senator John McCain leading the charge.

McCain charged that the lease arrangement was a ripoff, and though Air Force officials claimed their accounting showed otherwise, Congress was unimpressed. The Air Force then tried to modify the deal -- but it imploded when it was discovered that Darleen Druyun, a senior Pentagon procurement official involved with the tanker program, had been hired into a senior position at Boeing. That in itself was not illegal, but she had negotiated with Boeing for the job while she was still working at the Pentagon, which was -- and worse, had also passed Boeing details of a proposal by the European Aerospace & Defense Systems (EADS), now Airbus Group, for a competing Airbus-based "Multi-Role Tanker-Transport (MRTT)". Druyun was convicted and did prison time, as did Boeing's chief financial officer, Michael Sears. Boeing was fined $625 million USD and the company's chief executive officer, Phil Condit, had to resign.

The Air Force ended up starting over on the tanker deal, initiating a competition for the "KC-X", as it was designated. In response, Boeing again submitted a design based on the 767, though distinctly different from the KC-767 tankers sold to Italy and Japan. EADS teamed with Northrop Grumman to offer a tanker based on the Airbus A330, essentially a variant of the MRTT that EADS had sold to Australia and several other air arms.

The A330-MRTT proposal would be available earlier; since the Air Force was in a hurry to make up for lost time, that meant a lot. The Airbus also provided better range and more auxiliary cargo carriage. As a result, the Airbus machine, the "KC-45", was selected in 2008. Boeing promptly challenged the deal, claiming the Air Force had "moved the goalposts" after issuing the spec, awarding the contract on different criteria than those given at the outset. The Government Accounting Office agreed with Boeing's complaint, and so the award was rendered null and void. The Air Force had to start over again.

That was not only frustrating but also embarrassing, since Northrop Grumman didn't feel they had any chance to win and so dropped out, leaving only Boeing as the "competitor" for the deal. Fortunately, the Air Force saved some face when EADS decided to compete on their own, again offering the A330-based MRTT. Boeing revised its design after losing in 2008, dropping plans to come up with a new variant airframe and choosing to base the KC-46A "NewGen" tanker on a 767-200. The KC-46A was selected as the winner, the primary factor being lower price.

Four prototypes of the "Pegasus", as it was officially named, were built. The first performed its initial flight on 28 December 2014; it lacked tanker kit, this "767-2C" machine being used for airframe systems tests and qualifications. The second was in full tanker configuration, while the third was also in 767-2C configuration, with both of these machines flying in 2015. The fourth, which took to the air in the spring of 2016, was in full tanker configuration. Initial service delivery was in early 2019.

* As introduced, the KC-46A looked much like the KC-767 machines, but under the skin it was somewhat different, being based on an unproduced "long-range freighter" version of the 767-200; the basic airframes of the KC-767s were also much the same as their airliner siblings, while the KC-46A had some airframe modifications. It was powered by two Pratt & Whitney PW4062 turbofan engines providing 267 kN (27,200 kgp / 60,000 lbf) thrust each, and had advanced avionics -- leveraged off the Boeing 787 Dreamliner, discussed below, with the KC-46A featuring much the same cockpit layout. The KC-46A had a drogue refueling pod under the centerline and each wing, for a total of three, and a boom refueling unit derived from that of the McDonnell Douglas KC-10. The KC-46A also featured a refueling socket of its own, on the top of the aircraft just behind the cockpit.

The KC-46A was defined a "multi-mission" aircraft, capable of transport operations. There was a large cargo loading door on the left front fuselage -- it seems Japanese and Italian KC-767s weren't fitted with the cargo door -- plus an internal cargo handling system, with total cargo load of up to 29,485 kilograms (65,000). Removeable seats could be fitted in place of cargo, with typical seating for 58 passengers and up to 114 in a pinch; the aircraft could also be fitted for medical evacuation, with a total load of 58 litters and seated passengers.

A total of 179 KC-46As are to be obtained, though orders beyond that are possible. Although the KC-46A fared poorly against the Airbus MRTT in international competition, the JASDF did order three from late 2015, to complement their existing KC-767J fleet, with deliveries from 2021. Israel ordered eight in 2020, with deliveries from 2025.

* It should be added that one stock 767-200ER was also converted to a "Multi-Mission Tanker Transport (MMTT)" for the Colombian Air Force by Israel Aerospace Industries (IAI), this machine featuring a drogue refueling pod under each wing, plus cargo-handling facilities or troop seating. In 2013, the Brazilian Air Force ordered three similar conversions from IAI of 767-300ER machines; the deal fell through, though IAI did test-fly a 767-300ER with a boom refueling unit. IAI has discussed a collaboration with Hindustan Aeronautcis LTD of India to upgrade 767s to tanker configuration -- with possible "smart tanker" options, such as modules for signals intelligence, communications relay, or "flying command post" operations.

BACK_TO_TOP* In the mid-1980s, Boeing began investigating a new jetliner in the size range between the 767 and 747, with 300 seats; one of the motivations was to provide a replacement for retiring Douglas DC-10 jumbo jets. Initially, the new aircraft was seen as a stretched 767 and was accordingly designated the "767-X" -- but as the investigation progressed, the 767 design ended up being tweaked further and further. Simply stretching the 767 to gain the desired number of seats made it too long for a typical airport ramp; when the program was finally given the green light for full development in October 1990, it envisioned a new aircraft only generally modeled on the 767, designated the "777".

Even then, much remained uncertain about the aircraft's design, with specifics ironed out through discussions with customers. Customers, it turned out, wanted a fuselage wider than offered by competing aircraft such as the McDonnell-Douglas MD-11 and the Airbus A340. The wide cabin was taken as a base reference, the 777 then being effectively designed from the "inside out". Although Boeing jetliners had traditionally used a "double bubble" cross-section, with a large "bubble" topside and a smaller bubble below, a purely circular cross-section seemed preferable.

That resolved, there was the question of the number of engines: two, three, or four. Four seemed the most practical given the size of the 777, but that would have increased expense; a tri-jet configuration could do the job, but fitting an engine in the tail would be structurally troublesome. Two engines would be optimal if sufficiently powerful new turbofans became available in a timely fashion. On talking to engine manufacturers about the prospect of such engines, all replied that it was basically not a problem. Two engines it was.

A new, big, aerodynamically efficient wing was required; the span was so wide as to lead to the inclusion of folding wingtips, for customers who thought the span was a difficulty for ground handling -- though as it turned out, nobody would. It might have been interesting to have one take off with its wingtips up; unless highly effective precautions were built into the aircraft, Murphy's law suggests it would have inevitably happened.

Two classes of 777s were envisioned, a transcontinental "A Market" class with a capacity of 375 passengers and an intercontinental "B Market" class with less passenger capacity and more fuel. Subvariants would be offered in each class for more range or capacity. Customer reaction was enthusiastic, and so the first prototype of the 777, a "777-200" variant, took to the air on 12 June 1994. Eight other aircraft joined the test program, with certification and customer deliveries in 1995.

* The 777-200 provides a baseline for the 777 family. It looked very much like the 767 to the point where the two could be somewhat difficult to tell apart, but it was substantially scaled up, with an empty weight about 80% greater; it was a monster of a twin-engine aircraft, with its handling on approach definitely suggesting a big machine. It was made mostly of aircraft aluminum, though 10% of the weight of the airframe was composite material.

There were, as with the 767, multiple options for engines, including PW4000, GE90, and Rolls-Royce RR800 turbofans. Depending on model, engine thrust ranged from 338 kN (34,500 kgp / 76,000 lbf) to a staggering 514 kN (52,400 kgp / 115,540 lbf) thrust. Of course, the heavier variants tended to have the more powerful engines. Along with sheer power, these engines also provided excellent fuel economy, low emissions, and low noise. Fuel stowage was in the inner wings and wing center section, with total capacity of 117,348 liters (31,000 US gallons). There was an APU in the tail.

The general flight surface arrangement broadly followed that of the 767, with double slotted flaps inboard on each wing, followed by an inboard aileron that also acted as a flap, then a single slotted flap, and finally an aileron. There was a full-span leading-edge slat, in seven segments, and spoilers -- two just forward of the inboard flap, five ahead of the outboard flap. Tail flight surface arrangement was conventional, with a trimming adjustable tailplane. Landing gear arrangement was like that of the 767, with two-wheel nose gear, retracting forward, and main gear retracting in from the wings towards the fuselage -- though in the case of the 777, each main gear had six wheels, in three rows of two.

___________________________________________________________________

BOEING 777-200:

___________________________________________________________________

wingspan:

60.93 meters (199 feet 11 inches)

wing area:

427.8 sq_meters (4,605 sq_feet)

length:

63.73 meters (209 feet 1 inch)

height:

18.51 meters (60 feet 9 inches)

fuselage diameter:

6.2 meters (20 feet 4 inches)

empty weight:

141,340 kilograms (311,600 pounds)

max take-off weight:

247,210 kilograms (545,000 pounds)

max cruise speed:

925 KPH (575 MPH / 500 KT)

ceiling:

13,135 meters (43,100 feet)

range (nominal):

13,430 KM (8,340 MI / 7,255 NMI)

___________________________________________________________________

The 777 was the first Boeing jetliner with a "fly-by-wire" flight control system, with a flight processor system, the "Aircraft Information Management System (AIMS)" at the core. Incidentally, the 777 was also the first such to be developed completely using a "computer-aided design" system. The 777 featured a "glass cockpit" with six flat-panel color displays, and had other features such as a GPS-INS with laser gyros.

There were two flight crew, with typical passenger capacity of 305 in a three-class arrangement; 375 or 400 in a two-class arrangement; and up to 440 in a ten-across one-class "cattle car" arrangement. There were four passenger doors on each side of the aircraft. Positioning of galleys and toilets fore, aft, and midsection was flexible, easily rearranged as per client request. There was a cargo hold under the floor of the passenger compartment. An optional crew rest module could be installed in the cargo hold, complementing a default crew rest module with two bunks on the flight deck.

* The initial 777-200 was followed by improved variants:

Boeing has worked hard to keep the 777 line up-to-date, adding small refinements to production and for upgrades. One was elimination of the tail bumper, as a minor aerodynamic improvement and for weight reduction; the aircraft's flight control system was revised to automatically spot a potential tailstrike, and compensate for it. There were smaller aerodynamic refinements as well. Other changes have included lighter insulation blankets, lighter hydraulic fluid, and smaller weight-reduction measures; interior changes; and engine component updates.

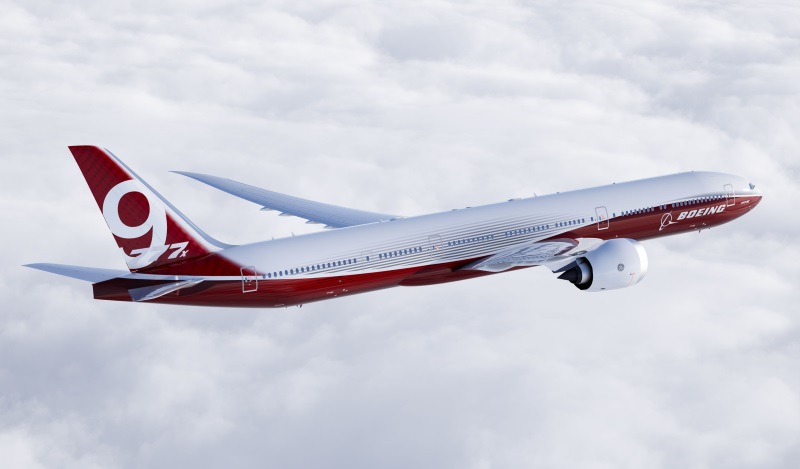

Over 1,750 777 jetliners had been built by the summer of 2025. Although the Boeing 787 is seen as the heart of the company's future, for the present the 777 is a good money-maker, and there are no plans to abandon it. In fact, Boeing has developed a next-generation "777X", featuring advanced GE9X turbofan engines and new all-composite wings, as well as weight reductions plus updated avionics and interior.

The first variant to fly was the "777-9X". The initial prototype was rolled out in 2019, with first flight of it and a second proto in early 2020. It was a stretched machine, with a range of 13,920 kilometers (8,655 miles / 7,525 NMI) in a 406-seat two-class layout; or 14,910 kilometers (9,270 miles / 8,060 NMI) in a 349-seat three-class layout. With an optional rear cargo door, it was able to haul 48 LD3 cargo containers in the lower hold, up from the 44 of the 777-300R.

The 777-9X had a length of 76.5 meters (251 feet), making it the longest airliner built to date. Its empty weight was only slightly less than that of a classic 747-400. It had an extended wingspan of 71.75 meters (235 feet 5 inches), with the wingtips folding up to ensure that the jetliner could fit into existing aircraft gates. The cockpit had five large color touchscreen displays, up from the six smaller displays of its predecessors. There was a holdup in development due to GE9X problems. Initial delivery was supposed to be early 2021; the COVID-19 pandemic threw a lot of confusion into the airline industry and the program ran into some snags, and now introduction to service of the production "777-9" is expected in 2025 or 2026.

A "777-8X" was planned as a follow-on -- being envisioned as a shortened 777-9X, with a length of 69.79 meters (229 feet). It was supposed to replace the 777-300R, with a long range of 16,075 kilometers (9,995 miles / 8,690 NMI) in a 365-seat two-class layout; or longer range of 17,160 kilometers (10,665 miles / 9,275 NMI) in a 303-seat three-class layout. Initial deliveries of the production "777-8" are not expected until 2028 at earliest; a "777-8F" freighter version is also to be built, and may be delivered first.

BACK_TO_TOP* From the beginnings of Airbus in the 1970s, the competition between Airbus and Boeing was intense and bitter, with each company denouncing and attempting to get the jump on the other. In 2000, Airbus committed to development of the "A380" super-jumbo jet, a giant aircraft that caught the imagination of the airlines. Boeing's reaction was clumsy, the company proposing major updates to the classic 747 jumbo jet and a new high-speed "Sonic Cruiser" -- both of which the airlines greeted with indifference.

Boeing officials ultimately decided not to match the A380. The A380 was predicated on a "hub & spoke" model of air travel, with a super jumbo jet only really practical to haul a mass of passengers between major hubs; passengers would have to transfer to other transport to get to "spoke" destinations. Boeing believed that what passengers wanted were more direct-to-destination flights, implying a smaller aircraft. In addition, fuel costs were on an upward curve, and so Boeing needed to make sure the new aircraft was as fuel-efficient as possible.

In early 2003, Boeing committed to the "7E7", which became the "787 Dreamliner" in 2005. The 787 was configurationally a twinjet along the lines, and roughly the size, of the 767, but it was a new-design aircraft, most significantly featuring widespread use of lightweight carbon-epoxy composite materials, the 787 to be one of the first large civil aircraft to be largely built of composites. A number of subcontractors were signed up for the project, with a consortium of three Japanese firms -- including Mitsubishi, Kawasaki, and Fuji -- coming on board as full risk-sharing partners, contributing about a third of the development cost. The Japanese had experience in construction of composite assemblies seen as critical to the 787 project.

Extensive use of composite materials allowed Boeing to consider new airframe construction concepts, abandoning the traditional aircraft framework and using large integral composite assemblies for strength. The idea was to obtain the maximum reduction in airframe weight to improve fuel economy -- though by taking such a new approach, problems with the composite assemblies would lead to program delays, and the weight savings wouldn't turn out to be quite as much as expected. However, along with being lighter, composites were also less prone to corrosion than traditional aircraft aluminum, and they were also easier to form into more aerodynamically-refined shapes.

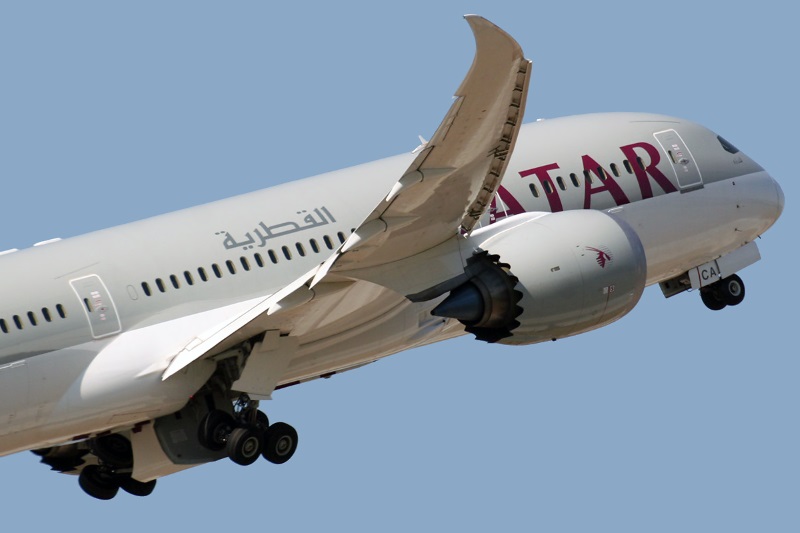

Three variants of the 787 were planned initially, including the baseline "787-8"; a stretched "787-9"; and a medium-haul "787-3", the last being canceled unbuilt. The first prototype of the Dreamliner, a 787-8, performed its initial flight 15 December 2009 -- about two years behind original schedule, development not having been entirely smooth. Six aircraft were flown in the test program, with initial delivery of a production machine, to the launch customer All-Nippon Airways, on 25 September 2011. The first prototype of the 787-9 performed its initial flight on 17 September 2013.

* As noted, as introduced the 787 had an overall configuration not all that different from its Boeing ancestors like the 767 and 777, being a low-wing aircraft with twin pylon-mounted turbofans, and all-swept flight surfaces; it was similar in size to the 767. It was, however, a completely new design. Along with an airframe half composites by weight, it had optimized aerodynamics; modern avionics; all electric systems; plus fuel-efficient, clean-burning, and quiet fanjets. Boeing claimed the 787 was easier, safer, and cheaper to operate, with 20% less fuel consumption than its predecessors.

Very significantly, while traditionally jetliners have used "bleed air" from the engines to drive most aircraft systems, the 787 was based on electric systems to perform cabin pressurization, de-icing, and other functions. The engines still had to provide the motive power for these systems by driving electric generators, but the overall result was more efficient, and replacing the cumbersome plumbing of bleed air ductwork with electrical wiring meant less weight.

The wings featured raked wingtips. Control surface arrangement was more or less along the lines of the 787's predecessors, with full-span leading-edge slats in seven segments, inboard flaps, inboard aileron, outboard flaps, outboard aileron, and spoilers leading the flaps. All flaps were single slotted; there were three spoilers ahead of the inboard flap, four ahead of the outboard flap. Sources have also mentioned a puzzling "sealing" leading-edge Krueger flap at each engine pylon, but details are unclear. The wings featured electrical de-icing. The tail surfaces were conventional, with rudder and elevators, the tailplane being adjustable for flight trim.

Customers could choose between two types of engines, the Rolls-Royce Trent 1000 or GE GEnx fanjets. Both were state of the art, providing high thrust-to-weight performance, improved fuel efficiency, low noise, and low emissions. Thrust levels were on the order of 311 kN (31,750 kgp / 70,000 lbf). The engine nacelles had a zigzag edge around the rear -- reducing exhaust noise, which not only translated into less need for aircraft sound insulation for passenger comfort, but fewer complaints from people living near airports. Boeing claimed the 787 noise footprint was only 60% that of the 777. Incidentally, the 777X engines didn't get the zigzag rear edge, since the GE9X were so quiet as to not need it.

The 787 had an APU for engine starting and ground power. There were fuel tanks in the inner wings and wing center section. There were two wheels on the nose gear, which retracted forward; there were four wheels on each main gear, in a 2x2 arrangement, with the main gear retracting inward, pivoting from the wings to the fuselage.

___________________________________________________________________

BOEING 787-8 DREAMLINER:

___________________________________________________________________

wingspan:

60.1 meters (197 feet 3 inches)

wing area:

325 sq_meters (3,501 sq_feet)

length:

56.7 meters (186 feet)

height:

17.1 meters (56 feet)

fuselage diameter:

5.74 meters (18 feet 10 inches)

empty weight:

108,860 kilograms (240,000 pounds)

max take-off weight:

227,890 kilograms (502,500 pounds)

max cruise speed:

955 KPH (590 MPH / 515 KT)

ceiling:

13,135 meters (43,100 feet)

range (nominal):

15,000 KM (9,316 MI / 8,100 NMI)

___________________________________________________________________

* The 787's interior design was particularly innovative. Passengers coming into the front of the aircraft entered through an open "lobby" instead of passing by a galley, being greeted by a blue LED lighting arrangement that suggested a skylight. The lighting was provided by LEDs throughout the passenger cabin; not only were the LEDs more reliable and less power-hungry, they also were more controllable, with lighting sequences designed to reduce flight weariness and, hopefully, jet lag.

Lighting remained standard during boarding and cruise flight, being adjusted to warmer tones during meals. After eating, the cabin was bathed in a relaxed lavender hue, with the lighting fading down when it was time to sleep. The most impressive part was the wake-up, with the light rising in a sunrise sequence from purples and oranges to yellows, and then white light against a blue sky.

As far as the annoyance of being hit in the eyes by the sun when somebody opens a window shade went, the 787 didn't have window shades: the windows used an electrochromic dimmer system. A passenger could change the transparency of a window with a switch, with the flight crew able to regulate the level of transparency of all the windows. Thanks to the composite construction, the windows were also 65% larger than on previous Boeing jetliners, with a tall aspect ratio so both kids and basketball players could see out.

While coach passengers couldn't expect to get much more of a footprint to themselves than before, the ceiling was arched to give more sense of spaciousness. The overhead storage bins were about 20% bigger, but they dropped down when opened and popped back up when closed to give more headspace. In addition, again thanks to the 787's composite construction, humidity could be increased without worries about promoting corrosion, and cabin pressure could be increased as well -- to an altitude equivalent of about 1,830 meters (6,000 feet) instead of the traditional 2,440 meters (8,000 feet).

The 787 was designed for very quiet operation, both to improve passenger comfort and to meet public noise regulations, with features such as the serrated rear edge of the engine nacelles previously noted. Even the fan blades were designed to be quieter. Another feature was a "Smoother Ride Control" capability in the aircraft's flight control system to reduce bumpiness from turbulence.

The flight deck featured an advanced glass cockpit, like that of the latest 777s. The flight crew had rest bunks fore and aft. There were twin aisles in all passenger sections, with 4-across seating in first-class, 6 in business class, and from 7 to 9 in economy class. Typical seating was 242 passengers in 3-class seating; 310 passengers in two-class seating; or 375 passengers in 1-class seating. There are four doors on each side. There was a cargo hold under the floor, all access doors on the right of the aircraft, with baggage doors fore and aft of the wing and a large cargo door in the rear. Cargo volume was 125 cubic meters (4,400 cubic feet).

Final assembly of the 787 was originally at the Boeing plant in Everett, Washington, but gradually shifted to a plant in North Charleston, South Carolina, which took over completely in 2021. Large assemblies are hauled in by four "747 Dreamlifter" cargo haulers, modified from 747-400 jetliners by fit of an oversized fuselage.

* The 787-9 was 6.1 meters (20 feet) longer than the 787-8, for a total length of 62.8 meters (206 feet); empty weight was about 6% greater. Passenger capacity was typically 280 seats in a three-class configuration, or 360 passengers in a two-class configuration. Boeing never publicized a one-class configuration -- but given that the 787-9 had about 16% more capacity than the 787-8, that would give approximately 435 passengers for "cattle car" operations. The 787-9 was originally supposed to have a wider wingspan than the 787-8, but the longer span led to excessive complications, and so Boeing turned to a scheme called "hybrid laminar flow control (HLFC)" to improve the efficiency of the shorter wing. Range was about 5% more than the 787-8. Deliveries began in 2014, the first customer being Air New Zealand.

In mid-2013, the company announced a "787-10" variant, stretched by 5.49 meters (18 feet) relative to the 787-9 to give a length of 68.3 meters (224 feet). Other than the stretch and modified landing gear to avoid tailstrikes, the 787-10 was much the same as the 787-9. Passenger capacity was 320 seats in a three-class configuration; range was only about 13,000 kilometers (8,450 miles / 7,000 NMI), the target market being high-density trunk routes and not very long range connections. Initial deliveries were in 2018, the first customer being Singapore Airlines.

Boeing offers VIP -- "Boeing Business Jet" -- configurations of the 787; an air freighter variant has been considered, but there's been no commitment to it. There has been very little discussion of military variants yet, though of course VIP variants are likely to be acquired as presidential aircraft. Boeing sees the market for aircraft in the class of the 787 as running to thousands over the next decades, and hopes to capture half that market.

Unfortunately, the service introduction of the 787 was marked by a number of technical problems and groundings, the worst being due to a set of battery-pack fires that attracted wide public attention. The big bugs are gone now, and the 787 is selling. Over 1,200 had been delivered by the summer of 2025.

BACK_TO_TOP* The 787 may represent the end of a line of Boeing jetliner evolution tracing back to the Boeing 707. The reason is fuel costs; fuel prices have been on a generally steady upward curve since the beginning of the 21st century, and simple economics demands that the next generation of airliners be far more fuel-efficient than the 787, even at some penalty in performance, or few customers will be able to afford to fly. Boeing has conducted research, partly in collaboration with the US National Aeronautics & Space Administration, on next-generation airliners. The more conservative concepts do follow current jetliner design schemes, but with greatly extended wings, with folding for ground handling.

A more radical design approach has focused on a "truss-braced wing (TBW)" configuration, with greatly extended (folding) wings reinforced by attaching a strut or truss. A Boeing design for such a TBW aircraft, made of composite materials, would have fuel savings of 40% using leading-edge high-bypass turbofan technology -- and over 60% with "hybrid" propulsion, for example electrically-driven propfans powered by fuel cells. The aircraft would only be about 10% slower than existing jetliners, an acceptable performance penalty.

Boeing worked with the US National Aeronautics & Space Administration (NASA) to fly the "X-66A Sustainable Flight Demonstrator". It was to be modified from an MD-90 jetliner, with the fuselage cut in length and fitted with a TBW, being powered by twin high-bypass turbofans, or possibly propfans. The program was put on hold in 2025, so it's not clear it will ever fly.

* One fact about the 767 that needs to be mentioned in this survey is the sad role two 767s played in the terrorist attacks on the World Trade Center towers in New York City on 11 September 2001. A hijacked 767-200ER, American Airlines Flight 11, was first deliberately crashed into the north tower, followed by the deliberate crash of a 767-200, United Airlines Flight 175, into the south tower about 15 minutes later, the resulting infernos causing the towers to collapse. Over 3,000 people were killed, including all on board the two jetliners.

On a more upbeat note, on 23 July 1983 a 767-200, Air Canada Flight 143, was en route from Montreal to Edmonton via Ottawa when it ran out of fuel due to a servicing error. The pilot managed to "dead stick" the powerless jetliner to touch down on an old airstrip at Gimli, Manitoba. Nobody was seriously hurt, and the "Gimli Glider", as it became known, returned to service, being finally retired in 2008.

Incidentally, the KC-46 designation for the USAF's 767 tanker more or less recycles the designation of the World War II Curtiss C-46 Commando transport. It is amusing to think that the KC-46A will acquire the original's nickname: "Dumbo", for the Disney flying elephant.

* Sources include:

A number of volumes of JANE'S ALL THE WORLD'S AIRCRAFT were consulted as well.

* Illustrations credits:

* Revision history:

v1.0.0 / 01 feb 13 v1.0.1 / 01 jan 15 / Brazil MTT, 787 updates, more on KC-46. v1.1.0 / 01 dec 16 / General update. v1.1.1 / 01 nov 18 / Review, update, & polish. v1.2.0 / 01 nov 20 / Review, update, polish, new illustrations. v1.3.0 / 01 aug 21 / Review, update, & polish. v1.3.1 / 01 aug 23 / Review, update, & polish. v1.3.2 / 01 sep 25 / Review, update, & polish. (!)BACK_TO_TOP