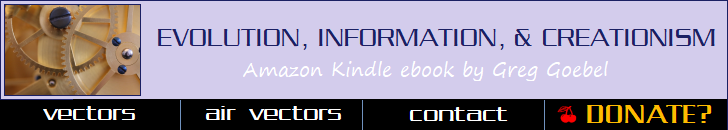

* The De Havilland aircraft company of England established a Canadian subsidiary in 1927, with De Havilland Canada (DHC) then building copies of designs such as the Tiger Moth trainer and the Mosquito bomber. After World War II, DHC increasingly went its own way, first designing the "DHC-1 Chipmunk" primary trainer, then the "DHC-2 Beaver" and scaled-up "DHC-3 Otter" bushplanes, leading ultimately to the turboprop-powered "DHC-6 Twin Otter" utility aircraft. This document provides a history and description of the Chipmunk, Beaver, Otter, and Twin Otter -- as well as the "Harbin Y-12", a Chinese aircraft similar to the Twin Otter.

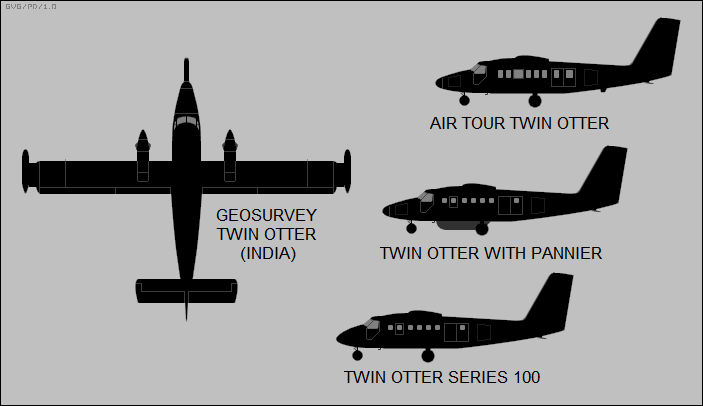

* After its establishment in the late 1920s, the de Havilland Canada concern initially provided service and support for its British parent firm, to then produce the tidy Tiger Moth biplane light aircraft series. During World War II, DHC built over 1,100 DH Mosquito twin-engine bombers. Given the massive expansion of DHC during the conflict, it wasn't surprising that the Canadian branch of the organization chose to go on to develop its own aircraft.

The very first DHC-designed product was a follow-on to the classic Moths, a modern tandem-seat piston trainer named the "DHC-1 Chipmunk" -- designed by a team under Wsiewlod J. "Jaki" Jakimiuk, a Polish designer who had worked for the PZL firm in his homeland until being chased out by the Nazis. The Chipmunk prototype performed its initial flight on 22 May 1946. It had a clear evolutionary relationship to the Tiger Moth, in particular being powered by a DH Gipsy inverted inline engine like the Tiger Moths, in the case of the Chipmunk the engine variant initially being the Gipsy Major 1C with 110 kW (145 HP), driving a two-bladed propeller.

However, while the Tiger Moth was a biplane with tandem open cockpits, the Chipmunk was a low-wing monoplane with an enclosed tandem cockpit. The DHC-1 was made mostly of aircraft aluminum, except for fabric-covered control surfaces and fabric covering the rear section of the wing; it had fixed taildragger landing gear, a conventional control surface layout, and was unarmed, with no provision for external stores.

218 Chipmunks were produced by DHC to 1951, the Royal Canadian Air Force (RCAF) being the primary buyer, most of these machines being fitted with a blown bubble canopy that slid back to open. Two models of the Chipmunk were built in Canada: the "DHC-1B-1" -- "Chipmunk Trainer Mark 1 (T.1)" to the RCAF -- which was essentially the same as the prototype, and the "DHC-1B-2" -- "T.2" to the RCAF -- which had a Gipsy Major 10 engine and was fully aerobatic. A number were also exported, some of them designated "T.30".

Two Chipmunks were evaluated at Boscombe Down in the UK in 1950, leading to a production order from the British Royal Air Force (RAF) for the type as primary trainer to replace the Tiger Moth, these machines being built by the parent company in Britain. De Havilland of the UK manufactured 735 "Chipmunk T.10" machines for the RAF -- with a Gipsy Major 8 engine and framed canopy that also slid back to open, featuring bulged side panels in the rear to improve the view of the flight instructor in the back seat. Some of the RAF T.10s were used for liaison duties in Europe, the back-seat controls being removed.

DHC UK built more 217 Chipmunks for a range of export users, under the designation of "Chipmunk Mark 20", with a few dozen also built new for civilian fliers, as the "Chipmunk Mark 21", and retired T.10s recycled for civil use as the "Chipmunk Mark 22" or, in crop-duster configuration, "Chipmunk Mark 23". 60 Chipmunks were license-built in Portugal by General Aeronautical Material Workshops (OGMA in its Portuguese acronym) for the Portuguese Air Force, giving total construction of 218 + 735 + 217 + 60 = 1,230 Chipmunks.

___________________________________________________________________

DE HAVILLAND CANADA DHC-1 CHIPMUNK T.10:

___________________________________________________________________

wingspan:

10.45 meters (34 feet 4 inches)

wing area:

16.03 sq_meters (172.5 sq_feet)

length:

7.75 meters (51 feet 9 inches)

height:

2.13 meters (7 feet)

empty weight:

646 kilograms (1,425 pounds)

MTO weight:

915 kilograms (2,015 pounds)

max cruise speed:

185 KPH (115 MPH / 100 KT)

service ceiling:

4,815 meters (15,800 feet)

range:

450 kilometers (280 MI / 245 NMI)

___________________________________________________________________

The "Chippie", as it was nicknamed, was obtained by military services in Burma, Ceylon, Chile, Colombia, Denmark, Egypt, Iraq, Ireland, Jordan, Lebanon, Malaya, Saudi Arabia, Syria, Thailand, and Uruguay. Most were out of official service by the 1990s, but hundreds of airworthy Chipmunks survive in private hands. Civilian Chipmunks have sometimes been refitted with Lycoming or Continental flat-six engines to give them more power, along with a distinct appearance. A number were converted to high-performance stunter configurations as "Super Chipmunks".

BACK_TO_TOP* While de Havilland Canada was working on the Chipmunk trainer, the firm was also developing a "short take-off & landing (STOL)" machine oriented towards "bush" operations, with exploitation of the Canadian Far North in mind. The design team was led by Jaki Jakimiuk. The first flight of the "DHC-2 Beaver" was on 16 August 1947 with test pilot Russ Bannock at the controls, the type receiving certification in 1948.

As it emerged, the Beaver featured a high-mounted straight wing with bracing struts, powered by a Pratt & Whitney (PW) R-985-AN-14B or -16B Wasp JR air-cooled nine-cylinder single-row radial engine providing 335 kW (450 HP), driving a two-blade variable-pitch Hamilton Standard propeller. The wing featured single slotted flaps and "drooping" ailerons or "flaperons" that operated as flaps on take-off, in effect giving full-span flaps.

The Beaver featured rugged fixed taildragger landing gear, the main gear featuring "nutcracker" shock absorbers -- the main gear was hinged, with rubber pads between the top of the gear leg and the fuselage to provide cushioning, a scheme that would be retained in the Beaver's fixed-gear successors. It could also be fitted with float or ski landing gear. When fitted with floats, the tailplane was fitted with "finlets" to improve yaw stability. Incidentally, DHC's Downsview plant in Toronto didn't have direct access to open water, and so float-equipped Beavers took off on a trolley for delivery, the trolley remaining on the runway after take-off. Some Beavers were fitted with oversized "tundra tires" to allow them to operate off of rough fields in the northlands.

The Beaver could carry a pilot plus 5 passengers or 680 kilograms (1,500 pounds) of cargo. There was a crew door on each side of the cockpit and a passenger door on both sides in mid-fuselage, each passenger door featuring a trapezoidal window that provided a distinctive recognition feature. There was a little porthole on each side of the upper rear fuselage.

The "Beaver I" earned an admirable reputation for utility, reliability, and ruggedness in the bushplane and agricultural roles. It was no speed demon, but that wasn't so important for the bushplane role -- one bush pilot was said to have told DHC: "You only have to be faster than a dog sled."

46 Beaver Is were obtained by the British Army as the "Beaver AL Mark 1", while 968 were produced for US forces into 1960 -- initially as the "YL-20" for evaluation, production machines being designated "L-20A", except for six "L-20B" machines with a slightly different equipment fit. Surviving L-20As were redesignated "U-6A" in 1962, when the US military adopted a common aircraft designation scheme.

The Beaver flew with the US military in the Korean War, being used in the utility and air-ambulance roles. Cargoes were often carried underwing to be dropped to frontline units. By the 1980s, most US military Beavers had been retired, many ending up in civilian hands, but a handful of Beavers lingered in service with US military test pilot schools beyond the end of the century, the type being seen as well-suited to introducing pilots to the handling of STOL aircraft.

___________________________________________________________________

DE HAVILLAND CANADA DHC-2 BEAVER:

___________________________________________________________________

wingspan:

14.63 meters (48 feet)

wing area:

23.22 sq_meters (250 sq_feet)

length:

9.25 meters (30 feet 4 inches)

height:

2.74 meters (9 feet)

empty weight:

1,295 kilograms (2,850 pounds)

MTO weight:

2,315 kilograms (5,100 pounds)

max cruise speed:

230 KPH (145 MPH / 125 KT)

service ceiling:

5,485 meters (18,000 feet)

range:

1,250 kilometers (780 MI / 675 NMI)

___________________________________________________________________

Other military users that obtained the Beaver in small to moderate numbers included Argentina, Australia, Austria, Cambodia, Chile, Colombia, Cuba, Dominican Republic, Finland, Ghana, Haiti, Indonesia, Iran, Kenya, South Korea, Laos, the Netherlands, Oman, Peru, the Philippines, Thailand, Turkey, Uruguay, Yugoslavia, and Zambia. Ironically, the RCAF never demonstrated much interest in the type. A total of 1,657 Beaver Is was built into the early 1960s.

One "Beaver II" was built, featuring an Alvis Leonides radial engine and a three-bladed prop; it performed its first flight 10 March 1953, but there were no orders. De Havilland Canada began work on a turbprop-powered Beaver in June 1963 -- with the "Turbo Beaver Mark III", powered by a Pratt & Whitney Canada (PWC) PT6A-6A (later PT6A-20) turboprop providing 410 kW (550 SHP) -- performing its initial flight on 30 December 1963. The additional power and the need to maintain center of gravity led to a fuselage stretch via a 71-centimeter (28-inch) fuselage plug forward of the wing that allowed two more passengers to be carried, for a total of seven. 60 Turbo-Beavers were built by DHC to end of production in 1967.

* There have been turbo conversions of piston Beavers by third parties, most using the PWC PT6A, though at least one had a Garrett AiResearch TPE331 turboprop engine. The best-known turbo conversion is the "DHC-2T Turbo Beaver" from Viking Air of Victoria, Canada, which in 2006 obtained all rights to the "classic" DHC machines from Bombardier Aerospace; Boeing had bought up DHC in 1986, with Bombardier then obtaining the operation in turn from Boeing in 1992. Bombardier only retained the Dash-8 twin turboprop airliner in the transfer to Viking Air. The DHC-2T has a PWC PT6-34 engine providing 510 kW (680 SHP), and an accordingly enhanced load capability.

Some updated Beavers retain piston power; while the Wasp JR is long out of production, PZL of Poland still sells the PZL-3S seven-cylinder radial, originally designed by Ivchenko in Russia as the AI-26, with 450 kW (600 HP). 21st-century piston Beavers seem to often sport three-bladed props. Updated Beavers have featured a wide range of other mods -- for example additional doors, additional windows, bulged windows, crew comforts, and modern avionics such as Global Positioning System (GPS) navigation satellite receivers -- with jazzed-up machines sometimes of course advertised as "Super Beavers". Garmin glass cockpit upgrades and the like are also now available for the Beaver.

BACK_TO_TOP* The Beaver doing well for de Havilland Canada, the firm decided to build a "bigger and better" Beaver, originally named the "King Beaver" but which emerged as the "DHC-3 Otter". Initial flight of a prototype was on 12 December 1951, with George Neal at the controls. Initial service deliveries were in 1952.

The Otter had a general configuration so similar to the Beaver that someone inexperienced with aircraft could confuse the two -- except if they were seen side-by-side, since the Otter was much bigger than the Beaver. The Otter had a load capacity of 10 or 11 passengers or 1,015 kilograms (2,240 pounds) of cargo at the outset, the Otter being qualified eventually for 14 passengers or 1,430 kilograms (3,150 pounds) of cargo. It was powered by a PW R-1340-S1H1G Twin Wasp radial with 445 kW (600 HP), driving a three-bladed variable-pitch propeller.

The wing featured, in effect, full-span trailing-edge double slotted flaps -- in two sections on each wing, the trailing element of the outer section being a flaperon. There was a crew door on each side of the cockpit, a large double door for cargo loading on the left rear of the fuselage, with a small passenger door facing it on the right. When equipped with floats, a ventral fin was fitted in place of the tailwheel for yaw stability.

___________________________________________________________________

DE HAVILLAND CANADA DHC-3 OTTER:

___________________________________________________________________

wingspan:

17.68 meters (58 feet)

wing area:

34.84 sq_meters (375 sq_feet)

length:

12.75 meters (41 feet 10 inches)

height:

3.84 meters (12 feet 7 inches)

empty weight:

2,010 kilograms (4,430 pounds)

MTO weight:

3,630 kilograms (8,000 pounds)

max cruise speed:

220 KPH (140 MPH / 120 KT)

service ceiling:

5,370 meters (18,800 feet)

range:

1,410 kilometers (875 MI / 760 NMI)

___________________________________________________________________

One Otter, the "Otter 3682", was modified as part of a "Super STOL" research project with very large flaps, a much taller tailfin, and quadricycle landing gear. The flaps were then removed, and a General Electric J85-GE-7 turbojet with 10.9 kN (1,100 kgp / 2,450 lbf) thrust was installed in the rear fuselage, with a pivoting exhaust on each side.

In its final configuration, the Otter 3682 had a PWC PT6A turboprop on each wing, which provided not only more power but "upper surface blowing" to reduce landing speed. Take-offs and landings of the Otter 3682 were said to be exciting to watch; they were said to be even more exciting for passengers who weren't familiar with what the aircraft could do, the reaction to a landing approach being a sense of imminent doom, usually leading to relieved laughter after touchdown.

* 466 Otters were built to end of production in 1967. Most of the production was for military use, with 69 supplied to the Royal Canadian Air Force as the "CSR-123" for search and rescue (SAR). 196 were sold to the US Army as the "U-1A" and 10 were obtained by the US Navy -- not counting four RCAF "loaners" provided to the USN as well -- for Antarctic service as the "UC-1", the Navy machines being redesignated "U-1B" in 1962. US Army Otters saw service in the Vietnam conflict. The Indian Air Force was another enthusiastic operator, obtaining 27 new, followed by ten more RCAF hand-me-downs. Other military users included Argentina, Burma, Chile, Ghana, and Norway.

The Otter was also sold in fair numbers to civilian users around the world, and once phased out of government service, many military Otters ended up in civilian hands. They served faithfully in bushplane, agricultural, and fire-bomber roles -- the last generally in floatplane configuration, the Otter setting down on a lake and pumping water for fire drops into tanks inside the floats -- and remain a prized mount in the 21st century. A good number were converted to turboprop power by after-market companies as "Turbo-Otters", sometimes at least informally designated "DHC-3T". The typical turbine powerplant is the PT6A, though there have been conversions with the Honeywell TPE331 and the Czech Walter 601.

Piston-powered Otters also remain flying in the 21st century, using the PZL nine-cylinder ASz-62IR radial -- originally designed by Shvetsov in Russia as the ASh-62 -- with 750 kW (1,000 HP). At least in some cases they're fitted with four-bladed props, and of course refurbished Otters are tuned up with fancier modernized kit, much as are refurbished Beavers.

BACK_TO_TOP* The Otter being popular, in the early 1960s de Havilland Canada decided to extend that design as well, fitting it with twin turboprop engines and giving the aircraft a general makeover. The prototype of the "DHC-6 Twin Otter" -- the "DHC-4" was the bigger Caribou transport and the "DHC-5" was its successor, the Buffalo, discussed elsewhere -- performed its initial flight on 20 May 1965, with certifications following and initial customer deliveries the next year.

The initial production "DHC-6 Series 100" model provides a baseline for the type. While the wing of the Twin Otter was derived with a modest stretch in span from that of the Otter -- featuring much the same high-lift configuration of double slotted flaps with flaperons, and bracing struts -- the rest of the DHC-6 wasn't directly taken from the DHC-3. The boxy fuselage clearly followed from that of the Otter, but:

From 13 to 18 passengers could be carried in various "airliner" or utility arrangements. Typically an airliner had two-row seating; there were crew doors on each side of the cockpit, a hatch on top behind the cockpit, and a door on each side of the rear fuselage -- the door on the left being configured as a fold-down "airstair". Utility machines had fold-down seats along the interior walls and a double cargo door on the left rear instead of the airstair door. As with the Otter, the Twin Otter was unpressurized. Ski or float landing gear were available as options -- float-equipped machines had finlets and wing fences -- and tundra tires were sometimes fitted as well. As with the Otter, float-equipped Twin Otters were used for water bombers.

Sales to civil operators were brisk, though military services were slow to jump on board. Eight were eventually sold to the RCAF; these machines were designated "CC-138", being painted in bright yellow and red colors for SAR duties.

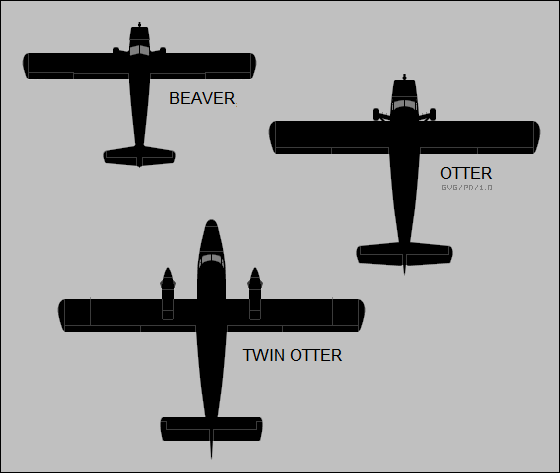

115 Series 100 Twin Otters were built, with production then shifting to the "Series 200", with a longer nose for greater baggage capacity. Somewhat confusingly, seaplane Series 100s retained the short nose, presumably because it was inconvenient to access the nose compartment from a dock. Amphibian machines, capable of operating from either a runway or water, apparently did sometimes have the long nose.

115 Series 200s were built as well, with production then moving on to the definitive "Series 300" -- much the same externally as the Series 200, but with uprated PT6A-27 engines providing 460 ekW (620 SHP), permitting a load of 20 passengers. Other changes to the Series 300 included emergency exits on each side of the forward fuselage -- the topside hatch was deleted -- and improved fire protection.

At least six of the Series 300 machines were built in "Series 300S" configuration, being used experimentally on an "Airtransit" city-to-city commuter run between Montreal and Ottawa. The Series 300S aircraft featured improved brakes, wing spoilers, general systems improvements, and fancy airliner-style accommodations for 11 passengers. It was an interesting idea, but it didn't pan out. The exercise did lead to the DHC-7 four-turboprop STOL airliner.

___________________________________________________________________

DE HAVILLAND CANADA DHC-6 TWIN OTTER SERIES 300:

___________________________________________________________________

wingspan:

19.8 meters (65 feet)

wing area:

39.02 sq_meters (420 sq_feet)

length:

15.77 meters (51 feet 9 inches)

height:

5.94 meters (19 feet 6 inches)

empty weight:

3,365 kilograms (7,415 pounds)

MTO weight:

5,670 kilograms (12,500 pounds)

max cruise speed:

340 KPH (210 MPH / 180 KT)

service ceiling:

8,140 meters (26,700 feet)

range:

1,300 kilometers (805 MI / 700 NMI)

___________________________________________________________________

A few Twin Otters were built with oversized passenger windows for "air tour" operations; a third party vendor offered a belly cargo pannier, but it apparently didn't sell, photos of Twin Otters with a pannier being very rare. Sources also mention optional wingtip tanks, but if they actually existed they appear to have been another unusual fit. A number of Twin Otters were converted to survey applications with magnetometer booms, camera systems, and other instrumentation.

DHC built a militarized transport variant of the Twin Otter, the "DHC-6 Series 300M", capable of paratroop operations; an armed configuration with four stores pylons for "brushfire" conflicts was offered, but there were apparently no takers. A "DHC-6 Series 300MR" for maritime patrol was introduced, featuring a search radar under the nose, a searchlight under the wing, and bulged observation windows, but it seems only one was sold.

The US military obtained the Twin Otter in small numbers as the "UV-18", including:

There are tales, probably true, that Twin Otters are used by the US Special Operations Command (SOCOM) for covert operations in the boondocks. Other military operators included Chile, Ecuador, Ethiopia, France, Jamaica, Norway, Panama, Paraguay, and Peru. The last DHC-built Twin Otter was rolled out in December 1988, after production of 844 machines.

* Upgrades have been offered for the Twin Otter, and Viking Air has introduced a new-build "Twin Otter Series 400" -- with first flight on 1 October 2008, the prototype being an upgrade from a Series 300. The Series 400 features a Honeywell Primus Epic glass cockpit, and further uprated PT6A-34 engines providing 560 kW (750 SHP). There were various other tweaky enhancements to the airframe, most significantly the introduction of composite elements to reduce weight. The company sells a "Guardian 400" subvariant for maritime patrol, featuring:

Viking Air is getting brisk sales with the Series 400, at least by the company's standards, building a handful a month being seen as ambitious. Peru obtained a dozen, while Vietnam bought six -- all six on floats, three in patrol configuration, the other three in airliner / VIP transport configuration. The US Army Golden Knights replaced their old Twin Otters and a Pilatus Porter with three Viking Series 400 machines. The company has been working on an update to the Twin Otter, with the focus in increasing gross weight; improving reliability, reducing maintenance costs, and reducing operating costs; and expanding the range of missions the aircraft can perform.

Along another line, the Ampaire company of Hawthorne, California, has been working on a hybrid-electric derivative of the Twin Otter, to be named the "Eco Otter SX". Schedule was not clear at last notice.

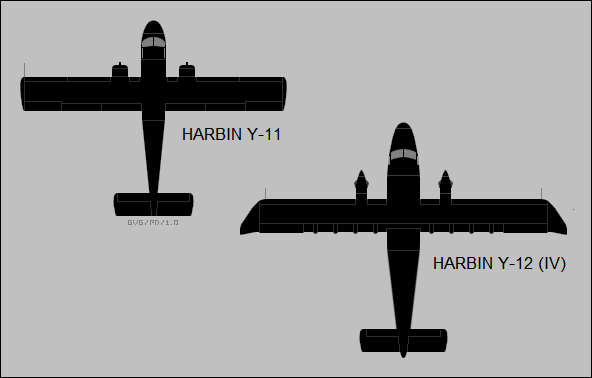

BACK_TO_TOP* The Twin Otter is such a straightforward design for a twin-turboprop "bushplane" that it's not too surprising there are a number of other twin-turboprop machines with a similar appearance: high straight wing with bracing, fixed tricycle landing gear, double side cargo doors. The resemblance is particularly close in the case of the Chinese "Harbin Y-12".

In the 1970s, the Chinese began to search around for a replacement for the Soviet Antonov An-2 utility biplane, then being built in China as the "Yunshuji 5 (Y-5 / Transport Type 5)". That effort led to the prototype of the "Y-11" performing its first flight in 1975. It had a general arrangement like that of the Twin Otter -- but instead of twin turboprops, it was powered by twin HS6A radial engines with 215 kW (285 HP) each. It was one of the first aircraft of purely Chinese design; it went into production in 1980, being used as a light airliner and agricultural aircraft.

The Y-11 had a wingspan of 17 meters (55 feet 9 inches), a length of 11 meters (36 feet 1 inch), and a maximum take-off weight 3,500 kilograms (7,715 pounds). Not much other data is available on the Y-11; apparently it was only built in modest numbers, a few dozen machines. A "Y-11B" prototype was flown in 1990 -- with flat-six air-cooled turbocharged TSIO-550-B Teledyne Continental engines providing 260 kW (350 HP) each in place of the radials to provide better "engine-out" performance -- but it never went into full production.

There was no need for it. Harbin had already flown a turboprop derivative of the Y-11, originally designated the "Y-11T" but finally redesignated the Y-12. Initial flight of the Y-12 was on 16 August 1984; the aircraft had a larger cabin than the Y-11 and was powered by twin PWC PT6A-11 turboprops, driving three-bladed Hartzell reversible propellers. The Y-12 looked so much like a Twin Otter that it could be confused for one at a glance, though it did have clear distinguishing features, including a ventral fin, a tailfin fillet, and a different landing gear arrangement -- still a fixed tricycle configuration, but with the main gear mounted vertically on little stub wings, which also served as the attachment point for the wing braces. The Y-12 was also distinctly smaller, with an empty weight 90% that of the Twin Otter.

Only a few baseline Y-12s were built, the variant being immediately followed by a second series, the "Y-12 II", from 1984, the primary improvement being PT6A-27 turboprops with 460 kW (620 SHP) each. It deleted the leading-edge wing slats of the Y-12, and also had a smaller ventral fin.

The Y-12 features a crew of two, both with flight controls, with access to the cockpit via a door on the left. The double doors on the rear left have a tip-out passenger stair. There are emergency exits on both sides forward, plus one opposite the double doors on the right side of the fuselage. There is a baggage hold in the nose, with the door on the left side, and a baggage hold in the rear, with the door on the right rear. The cabin is unpressurized, but an oxygen system is available as an option. A color weather radar can also be obtained as an option. A single stores pylon can be fitted outboard of the wing brace, it seems primarily to handle external fuel tanks. Along with airliner configurations, the Y-12 can also be configured as a cargo hauler, air ambulance, agricultural aircraft, fire fighter, or survey machine -- photos show the existence of Y-12s with sensor turrets or tail sensor booms.

___________________________________________________________________

HARBIN Y-12 II:

___________________________________________________________________

wingspan:

17.235 meters (56 feet 6 inches)

wing area:

34.27 sq_meters (368.9 sq_feet)

length:

14.86 meters (48 feet 9 inches)

height:

5.575 meters (18 feet 4 inches)

empty weight:

3,000 kilograms (6,600 pounds)

normal weight:

4,500 kilograms (9,920 pounds)

MTO weight:

5,300 kilograms (11,685 pounds)

max cruise speed:

290 KPH (180 MPH / 155 KT)

service ceiling:

7,000 meters (23,000 feet)

range:

1,350 kilometers (815 MI / 725 NMI)

___________________________________________________________________

The Y-12 II was to be followed by a "Y-12 III" AKA "Y-12C" with domestically-produced WJ9 turboprops, but this variant was only produced in small numbers, if it entered production at all. As a result, the next main production version was the "Y-12 IV", introduced in the mid-1990s; it retained the PT6A-27 engines, but added a number of features, most visibly raked wingtip extensions, extending the span to 19.2 meters (63 feet). Other refinements included a re-arranged interior, capable of seating 19 passengers in a three-across configuration, and a higher maximum take-off weight.

The "Y-12E" followed the Y-12 IV, the major difference being PT6A-135A version is the "Y-12E", the major difference from the Y-12 IV being PT6A-135A turboprops de-rated to 660 kW (620 SHP), driving Hartzell four-bladed reversible metal propellers. The latest version is the "Y-12F", which is almost a new aircraft: wider fuselage, no wing bracing, and retractable landing gear, with the nose gear retracting forward and the main gear tucking into sponsons.

Exactly how many Y-12s have been built so far is not known, the number being between 100 and 200. Outside of China, it is operated by over a dozen nations, mostly in the developing world, including Cambodia, Eritrea, Guyana, Iran, Kenya, Mauritania, Mongolia, Myanmar, Namibia, Pakistan, Paraguay, Peru, Sri Lanka, Tanzania, Uganda, and Zambia.

A number of alternate variants of the Y-12 have been discussed by the Harbin firm, including "special mission" configurations, but the status of such projects is unclear. The Chinese AVIC company is now obtaining floats from the Edo firm of the US to update Y-12s as floatplanes, with an eye towards export sales, presenting a greater competitive challenge to the Otter.

BACK_TO_TOP* I have no recollection of ever seeing a Beaver; I did spot an Otter at the US Navy air museum in Pensacola and got a shot of it, and I also once saw a Twin Otter at an airshow, carrying parachutists. While on a road trip over the Rockies in 2012, I spotted a number of Twin Otters at the airport in Grand Junction, Colorado; a local firm there was fitting them with large windows for the air tour trade.

* Sources include:

The online Wikipedia, Viking Air materials, and various editions of JANE'S ALL THE WORLD'S AIRCRAFT were consulted as well.

* Revision history:

v1.0.0 / 01 apr 12 v1.0.1 / 01 feb 13 / Rumors of SOCOM Twin Otters. v1.0.2 / 01 jan 15 / Review & polish. v1.0.3 / 01 dec 16 / Review & polish. v1.0.4 / 01 nov 18 / Review, update, & polish. v1.0.5 / 01 sep 20 / Review, update, & polish. v1.1.0 / 01 jul 22 / Review, update, & polish. v1.1.1 / 01 jun 24 / Review & polish.BACK_TO_TOP