* The Vulcan began life as a radical flying wing concept, and though it emerged in a modified form, it proved radical enough. The exotic looks weren't just for show: the Vulcan, in its B.1 and improved B.2 forms, would also prove an excellent aircraft.

* The Avro Vulcan was the second of the British Royal Air Force's (RAF) "V-bombers" to enter service. It was designed in response to British Air Ministry Specification B.35/46, which was issued at the beginning of 1947 and detailed a high-altitude, long-range nuclear strike bomber. The same requirement would also lead to the other V-bombers, the Vickers Valiant (the first V-bomber, designed as an "interim solution") and Handley-Page Victor (the third, built in parallel with the Vulcan) -- as well as the Shorts Sperrin, a much more conservative design intended strictly as insurance, with only two Sperrins built.

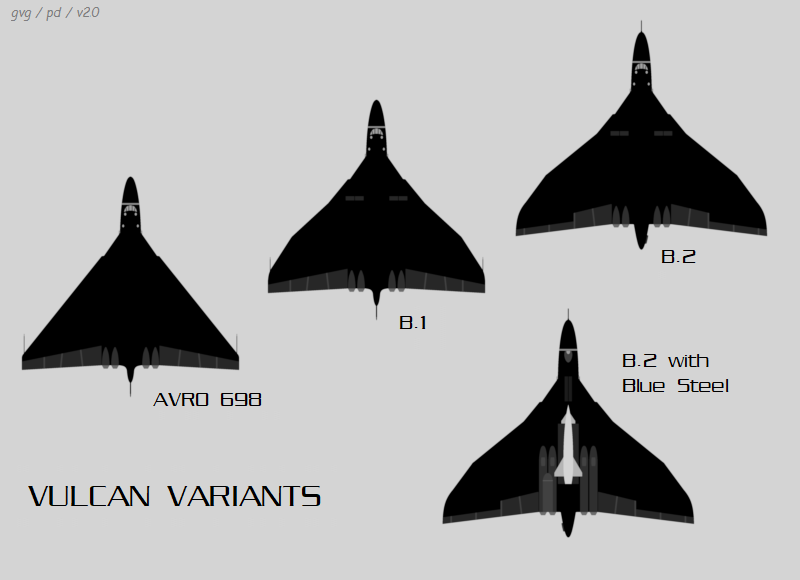

Avro's concept for the new bomber, which was given the company designation of "Type 698", envisioned a tailless delta. The original design featured tailfins on the wingtips, with twin Bristol BE.10 (later Olympus) turbojets stacked one above the other and staggered fore and aft in each wing root -- with both fed by a single large circular air intake -- for a total of four engines. The aircraft was more or less a flying wing, with a nose section tacked on forward of the wing; there was a weapons bay in each wing outboard of the engines.

The design seemed promising to the Air Ministry; a contract was awarded to Avro in December 1947 for a mockup, flight-test demonstrators, and two flight prototypes. The flight-test demonstrators were to include a single "Avro 710", a half-scale aircraft powered by twin Rolls-Royce Avon turbojets; and a number of one-third-scale single-engine technology demonstrators designated "Avro 707", powered by single Rolls-Royce Derwent turbojet. As work proceeded on the demonstrators, the Avro 710 was judged too complicated, about as much effort as building a full-scale prototype, and so the Avro 710 was abandoned unflown, with work focusing on the Avro 707 demonstrators.

* The initial 707, tailcode VX784, performed its first flight on 4 September 1949, with Flight Lieutenant Eric Esler at the controls. The aircraft was absolutely a demonstrator, with canopy and nose gear obtained from a Gloster Meteor and main gear obtained from an Avro Athena. It featured the engine intake on the back. All seemed well with the aircraft, which demonstrated good handling -- until it crashed on 30 September, killing Esler. Its airbrakes had stuck open, causing a low-speed stall.

Changes were made to the design, and the "707B", tailcode VX790, performed its first flight on 6 September 1950, with Wing Commander R.J. "Roly" Falk at the controls. The second aircraft was much like the first, except for a longer nose; fit of an ejection seat, which the first demonstrator had lacked; use of nosegear from a Hawker P.1052 instead of a Meteor; and of course revisions to the airbrake system, plus some other tweaky changes. The agility of the type proved outstanding.

The original Avro 707 had been strictly a low-speed machine and was to be followed by a "high speed" demonstrator, the "707A", but in mid-construction the 707A was "decapitated", with its nose section cut off, to be fitted to the 707B VX790; the aircraft, tailcode WD280, performed its first flight on 14 July 1951. It featured a number of changes, in particular rectangular intakes in the wingroots. It was later refitted with a "kinked" delta wing, featuring a shallower sweep in midsection, instead of the straight delta configuration that it had been born with.

A second 707A, tailcode WZ736, was built, performing its initial flight on 20 February 1953; it was never refitted with the kinked wing. It was delivered straight to the Royal Aeronautical Establishment (RAE) as a trials machine. Yet another demonstrator, the "707C", tailcode WZ744, with side-by-side seating for two crew, was built, performing its initial flight on 1 July 1953. It was supposed to be the basis for a pilot trainer for the full-scale Avro 698, but a pilot trainer would prove unnecessary; it also ended up in the hands of the RAE as a trials machine.

A total of five 707 demonstrators was built:

The whole 707 demonstrator program was undermined by the fact that work on the actual Avro 698 moved so quickly; the design was all but finalized by the time the first 707 flew. However, the 707s did prove useful in test and trials, as well as in familiarizing a set of pilots in delta-wing handling. Three 707s survive today as static displays.

* The Avro 698 that emerged from the development program retained the delta wing configuration and the four Olympus powerplants of the initial design concept, but differed in many other respects. The prototypes featured a single central tailfin; twin engines arranged side-by-side in each wingroot and fed through a rectangular inlet in the wingroot leading edge; a distinct fuselage between the wings; and a central weapons bay. The prototypes were built with a wing featuring a straight leading edge.

The initial Type 698 prototype, tailcode VX770, took to the air on 30 August 1952, with Roly Falk at the controls. Although the production aircraft was to be powered by four Bristol Olympus turbojets, they were not available at that time, and so the prototype was powered by four Rolls-Royce RA.3 Avon turbojets with 28.9 kN (2,950 kgp / 6,500 lbf) thrust each. It was painted in tidy overall white and with bright RAF roundels. There was some excitement during the initial flight when two landing gear door fairings fell off, but after inspection by a chase plane the aircraft was judged safe to land, and Falk put it down without incident. Although consideration had been given to naming the aircraft the "Ottawa", in line with the RAF tradition of naming bombers after cities, the new bomber was given the name "Vulcan" in October 1952.

After further trials flights, the initial prototype was re-engined with Armstrong Siddeley Sapphire Sa.6 turbojets providing 33.6 kN (3,400 kgp / 7,500 lbf) thrust, and also generally built up closer to production spec, with the improved machine returning to the air in June 1953. The second prototype, VX777, performed its first flight on 3 September 1953, fitted with Olympus 100 engines providing 43.4 kN (4,420 kgp / 9,750 lbf) thrust each; it had been previously fitted with lower-rated Olympus 99 engines for taxi tests. A week later, both Vulcan prototypes and the four surviving Avro 707 demonstrators performed a memorable formation flypast at the Farnborough air show.

The second prototype was damaged in a rough landing on 27 July 1954. It was rebuilt and refitted with uprated preproduction Olympus 101 engines, providing 44.5 kN (4,535 kgp / 10,000 lbf) thrust each, and returned to flight in February 1955. It was refitted with the "kinked" wing in October of that year, and would go on to further trials use. The first prototype never received Olympus engines or the kinked wing; it was refitted with Rolls-Royce Conway turbofans, then lost in a crash at an airshow at Syerston on 20 September 1958. The crew were killed, with the disintegration of the aircraft caught in a ghastly photograph.

* Although the prototypes didn't meet spec initially, further work produced a satisfactory design. 25 production "Vulcan B Mark 1 (B.1)" machines were ordered in July 1952, with the first Vulcan B.1 performing its initial flight on 4 February 1955. One of the first machines delivered crashed at Heathrow on 1 October 1956, on return from a demonstration flight to New Zealand and back. Two crew survived and four were killed, the accident being traced to improper landing directions from the airport tower while the bomber was trying to land in murky weather. However, the tragedy didn't slow down introduction to service much.

The Vulcan B.1 entered RAF service with the Number 230 Operational Conversion Unit (OCU) in early 1957, and reached line squadron service with Number 83 Squadron in July of that year. A total of 45 B.1s was built up to April 1959 and equipped five RAF squadrons, including Number 101, Number 44, Number 50, the famed Number 617 Squadron, and Number 83 Squadron. While the first Vulcan B.1s delivered for evaluation were painted overall silver, in service they were painted anti-flash white, with the radome in black. The RAF roundels were originally in bright colors, but were eventually changed to faded hues.

* While Avro was developing the Vulcan, in 1952 the company also promoted an airliner version, the "Type 722 Atlantic", which featured the wings and propulsion system of the bomber mated to an airliner fuselage. It would have had a capacity of 94 passengers in a normal configuration or 113 passengers in a high-density configuration. The passengers would sit on rear-facing seats -- a common configuration in military transports, since it improves crash passenger survivability.

The Atlantic would have been an advanced jetliner for the time, with a range of 6,440 kilometers (4,000 miles) at a cruise speed of Mach 0.9 and an altitude of 12,200 meters (40,000 feet). Nobody bit on the concept, with the only hardware produced being a neat scale cutaway model, demonstrating its attractive 1950s science-fiction lines. Some sources also mention that a concept was floated for a Vulcan operating as a "flying aircraft carrier", hauling three Folland Gnat lightweight fighters -- one under the centerline and one under each wing. However, that sounds like little more than a blue-sky idea that never got much farther than the back of an envelope.

BACK_TO_TOP* The Vulcan B.1 provided a useful baseline for description of the Vulcan family. It was a big tailless delta machine, built mostly of aluminum alloy, with sparing use of magnesium. It was powered by four Bristol Siddeley Olympus turbojets, two in a side-by-side configuration in each wingroot, with a slot-type intake in the wingroot leading edge and a half-circle "splitter plate" next to the fuselage to prevent the intakes from ingesting stagnant, turbulent "boundary layer" air from near the fuselage.

The B.1 was initially fitted with Olympus 101 engines with 49.0 kN (5,000 kgp / 11,000 lbf) thrust. Later production shifted to the uprated Olympus 102 with 53.5 kN (5,450 kgp / 12,000 lbf) thrust, and finally the even more powerful Olympus 104 with 57.9 kN (5,900 kgp / 13,500 lbf) thrust. As the more powerful engines were introduced, earlier machines were updated to them. The second B.1 featured an extended and slightly toed-out exhaust for the outer engine on each wing to make maintaining flight trim easier.

The two prototypes had been originally fitted with a simple delta wing with a 52-degree sweepback, but this configuration suffered from buffeting at high speed. The RAE proposed a kinked wing, with the sweep reduced to 42 degrees at one-third span and returned to 52 degrees at two-thirds span. The kinked or "Phase 2" wing was, as mentioned, evaluated on one of the two Avro 707A demonstrators, and refitted to the second Vulcan prototype. The first five Vulcan B.1s were actually delivered with straight delta wings in order to meet schedule, but were then refitted with the kinked wings while in service. There was a tailfin, but no tailplane.

The wing had twin spars, two ailerons, and two elevators at the trailing edge, plus fence-type airbrakes on the wing above and below the engines. There were twin side-by-side airbrakes in each of the four sets, but the outer airbrake in each lower set was later wired down to counter the aircraft's tendency to nose down when airbrakes were deployed at high speed. There were five bag-type fuel tanks in each wing and two rigid fuel tanks in the fuselage, for a total of twelve tanks. No more than 10% of the fuel load would be lost if any one tank were holed. The B.1 featured a complicated, manually-operated fuel management system to maintain flight trim as fuel was consumed.

The landing gear was of tricycle configuration, with the main gear in the wings just outside of the engines. Each main landing gear consisted of an eight-wheel bogie, organized as two rows of four wheels each, while the nose gear had two wheels and was steerable, using the rudder pedals. All the gear assemblies were long, giving plenty of ground clearance, and were hydraulically actuated. The nose gear retracted backward, while the main gear retracted forward. A brake chute was deployed from a door on the right side of the tailcone.

There were five crew, including pilot and copilot in the cockpit, along with a navigator, radar operation, and systems operator in a separate compartment behind them, this compartment being known as the "coal hole". There were also two jump seats for additional aircrew in the coal hole. There was a blister under the nose where the bombardier could lie prone to perform optical bombing, though it would rarely be used. The pilot and copilot had Martin-Baker Mark 3KS ejection seats, with the seats "handed" and not interchangeable -- but the crew in the rear had to bail out manually, though the seats could swivel and had what was vaguely described as an "assistor cushion" to help get out.

Entry to the aircraft was through a hatch just forward of the nose gear. The hatch had built-in steps and a swing-down ladder, with the ladder being easily thrown off if the crew were in a hurry to pile out. The bulged canopy had a five-panel windscreen and a porthole on each side; the canopy was easily removed for maintenance. There was a small porthole on each side of the coal hole, as well as a small fairing for sextant readings on the right, and a similar fairing for a flare pistol on the left.

The fact that there were no ejection seats for the three aircrew in the rear was cause for complaint, particularly in the occasional crashes in which the pilot and copilot escaped, but the rest of the aircrew didn't. In fact, the original design concept for all the V-bombers had envisioned the entire nose separating and falling to earth under a parachute assembly, but not surprisingly this concept proved impractical and was abandoned early on -- it was very difficult to design a parachute system that could land such a large assembly at a safe impact velocity. Martin-Baker developed an ingenious ejection system for the coal hole, in which a hatch popped open at the top, with the crewman in the center ejecting, and then each crewman shunted to the same position in his seat and shot out in turn. It was judged prohibitively expensive to implement, and the good safety record of the Vulcan suggests it wasn't all that necessary.

The pilot and copilot used a fighter-type stick, not a yoke control, the stick having been adopted at the insistence of Roly Falk. There was no autopilot system. The blunt nose was fitted with a dielectric panel for the EMI H2S navigation and bombing radar, a much improved descendant of the original H2S radar developed during World War II. Other cockpit systems included:

The only defensive countermeasures system was an ARI 18074 Green Palm voice channel jammer. The rationale behind this basic countermeasures fit was that at the time, the Soviet air-defense system was heavily dependent upon a "ground controlled intercept" scheme, in which interceptor pilots were guided to a target by ground controllers over a radio communications link; block the link, and the interceptors wouldn't be able to find the bomber. However, the Soviets were of course improving their defenses, and the simple approach would soon be seen as inadequate.

Bombload was over 9,450 kilograms (21,000 pounds), and was carried in the internal bomb bay in the fuselage. The bomb bay had a width of 3.2 meters (10 feet 6 inches), and the doors were 8.84 meters (29 feet) long; the bomb bay was big enough to fit the 40-kiloton Blue Danube fission bomb, which was still so huge that it had to have pop-out fins to fit. Other expected stores at the outset had been the Blue Boar rocket-boosted TV-guided bomb or the derivative Green Cheese antiship weapon, with two munitions to be carried on a sortie, but both these programs were canceled.

Later nuclear stores were, to no surprise, smaller than the Blue Danube. The US provided Mark 5 bombs under a joint program, but the security restrictions made training difficult and so they were never really a useful store. The Blue Danube was soon replaced by the lighter 500-kiloton Yellow Sun Mark 1 fusion bomb, and then the 1-megaton Yellow Sun Mark 2. The Vulcan could also carry the "small" 15- or 25-kiloton Red Beard tactical nuclear weapon -- it should be noted that this was in the yield range, even above that, of the munitions that destroyed Hiroshima and Nagasaki. As the smaller nuclear weapons were introduced, fuel tanks were installed in the Vulcan's bomb bay to extend range.

Of course, while the nuclear strike mission was emphasized in the early days, which coincided with the peak of the Cold War, the Vulcan was capable of conventional bombing as well. The usual load was 21 450-kilogram (1,000-pound) bombs, arranged in three tandem clips of seven bombs. The release pattern staggered drop of the bombs one at a time from the clip, with the munitions falling out in a "one-two-three" pattern repeated seven times.

* By 1958, the Vulcan B.1 was in full service with the RAF as a major component of Britain's nuclear deterrence. Cooperation with the US Air Force's Strategic Air Command (SAC) was tight, with the V-bombers and SAC bombers assigned specific roles in joint strike plans. Vulcans often participated in cooperative exercises with their SAC "cousins". Indeed, the RAF maintained a Vulcan service facility at Offutt Air Force Base in Nebraska, the main home of SAC, with Vulcans often flying in for exercises that ranged over the US and Canada. The Vulcans also often went home with prizes in bombing competitions.

The only sort of action the B.1 saw was in gunboat diplomacy, with a number being dispatched on a temporary basis to Malaya in the last phases of the insurgency there. These Vulcans were not used in combat, and apparently they were simply there to discourage outside interference in Malayan troubles. Vulcans would also occasionally perform individual long-range deployments, known as "Lone Rangers" or usually just "Rangers", during their first-line career, both to show the flag and to demonstrate the global reach of the Vulcan fleet.

BACK_TO_TOP* The Vulcan B.1 was not seen as overly survivable by the RAF. The service was looking forward to obtaining a Mach 2+ V-bomber -- it would never actually happen, more on that later -- but in the interim, effort focused on improvements to the existing Vulcan.

The Vulcan B.1's electronic countermeasures were clearly inadequate, and so an update program was instituted to provide the B.1 with a better countermeasures suite. The new suite included the original Green Palm voice channel jammer but added the following kit:

The new jammer system was fitted into a "fat" tailcone, with the brake chute moved to a blister on top. The tailcone featured a prominent cooling airscoop on the right side, and a little pivoting rod on the bottom to warn the pilot of a tailscrape on take-off. A flat plate antenna for the Red Shrimp jammer was faired over the bottom rear section of the right engines.

The updated aircraft were redesignated "Vulcan B.1A", with a total of 28 conversions taking place, the first machines being pulled from service for modification in July 1959 and the last returned to the RAF in March 1963. The updates were all performed by Armstrong-Whitworth, with some assistance from Vickers. Unmodified B.1s were pulled from first-line service with the final B.1A redelivery, to be retired or used in secondary roles, including as trials platforms.

* The new countermeasures suite had actually been developed for a more comprehensive redesign of the Vulcan, featuring improved high-altitude performance. Bristol Siddeley was working on improved variants of the Olympus with substantially greater thrust. The wing had to be modified, since the existing B.1 wing would be prone to buffeting at high engine thrust levels, and would also not be adequate to deal with the weight increase. The new "Phase 2C" wing would retain the "kinked" configuration, but span was to be extended from 30.2 meters (99 feet) to 33.8 meters (111 feet). The elevator-aileron control surfaces of the B.1 were also modified to act as combined "elevons".

Design work on the new variant, to be designated "Vulcan B.2", began in late 1955, with formal development go-ahead granted by the Air Ministry in May 1956. The second Vulcan prototype was refitted with the Phase 2C wing and Olympus 102 engines for flight evaluation, returning to the air in this configuration on 31 August 1957. Initial flight of the first production Vulcan B.2 was on 19 August 1958, with first service deliveries in July 1960.

Following workup by Number 230 OCU, RAF Number 83 Squadron was the first operator, the B.2 replacing the squadron's older B.1s beginning in the spring of 1961. Number 44, Number 50, and Number 617 Squadrons also soon replaced their B.1s with B.2s; four new squadrons -- Numbers 9, 12, 27, and 35 -- were built up from scratch with the B.2. For the time being, Number 101 Squadron stayed with the B.1A. All Vulcans were under the operational control of RAF Bomber Command (later Strike Command) Number 1 Group.

The last of 89 B.2s, the final Vulcan built, was delivered in January 1965. The first aircraft in the B.2 production run had actually been ordered as B.1s but built as B.2s. Total production of Vulcans was 2 Type 698 prototypes, 45 B.1s, and 89 B.2s, for 136 aircraft in all. The type was never exported or used by any other nation -- though pictures do survive of a Vulcan with New Zealander "kiwi" roundels, the aircraft being a victim of what we would now call "tagging" during a visit "DownUnda".

Early production B.2s were originally fitted with four Bristol Siddeley Olympus 201 turbojets with 75.5 kN (7,700 kgp / 17,000 lbf) thrust each. The Olympus 301, with 98.1 kN (10,000 kgp / 22,000 lbf) thrust, was used on later production, with about half the aircraft given this engine fit. There were plans to update the early machines to the Olympus 301, but though some sources claim it was done, changes in operational doctrine rendered it unnecessary and it never happened. The engine intake slot was altered slightly to support the airflow required by the more powerful engine.

___________________________________________________________________

AVRO VULCAN B.2:

___________________________________________________________________

wingspan:

33.83 meters (111 feet)

wing area:

368.3 sq_meters (3,964 sq_feet)

length:

30.45 meters (99 feet 11 inches)

height:

8.28 meters (27 feet 2 inches)

max loaded weight:

113,000 kilograms (250,000 pounds)

maximum speed:

1,040 KPH (645 MPH / 560 KT)

service ceiling:

16,765 meters (55,000 feet)

range:

7,400 kilometers (4,600 MI / 4,000 NMI)

___________________________________________________________________

The countermeasures system fitted to the Vulcan B.1A was fitted to the B.2, though early production didn't have the "fat tail" at first, being refitted with it later. Other modifications to the Vulcan B.2 included:

An inflight refueling probe was fitted in the nose, though early pictures don't show the probe, suggesting that it was added in later production and refitted to early machines. It was also refitted to B.1As. Initially, the B.2 was painted in anti-flash white with the black radome and subdued RAF roundels, just like the B.1A. A Vulcan B.2 could be a bit difficult to tell from a B.1A, particularly from side views -- but one giveaway was that the wingtip pitot tubes used on the B.1/B.1A were deleted from the B.2.

Along with the introduction of the B.2, in 1962 the RAF also introduced the "quick reaction alert (QRA)", in which crews and nuclear-armed aircraft remained on standby, getting into the air in minutes when the alarm sounded. A "simultaneous start" or "simstart" ground system was introduced to wind up all four Olympus turbojets together and get other necessary systems working. Special ramps known as "Operational Readiness Platforms (ORPs)" were installed at primary Vulcan bases, where two or four Vulcans could sit in waiting alongside the runway for an alert and then launch immediately in a group.

Once in the air, the Vulcan B.2 had excellent high-altitude performance, with its big wing allowing the bomber to maneuver with agility at heights where interceptors would be struggling to make a turn. Although not specifically designed with "stealth" in mind, the smooth curves of the Vulcan also meant few radar traps, and it could be tricky to spot on radar. Sources claim the crews called the machine the "Tin Triangle".

Vulcans were sent back to Southeast Asia from 1963 into 1966, during a period of border tensions between Malaya and Indonesia. The bombers operated on a rotation basis, the effort being codenamed MATTERHORN. They never fired a shot, but provided a hint to the Indonesians that Britain had some big sticks to hit them with. Of course, the Vulcan force also continued its tradition of visits to the USA to participate in SAC training exercises.

BACK_TO_TOP